VDL MAST SOLUTIONS TAKES THE BURDEN OFF THE CUSTOMER

FROM A TO Z

At VDL Mast Solutions, we aim to provide our customers with a complete solution, taking care of all aspects of the mast project from start to finish. Our services include:

Design and Engineering

Our talented designers, constructors, and engineers work closely with our customers to turn their vision into reality. Whether it involves developing a completely new mast design or adapting existing models, we ensure an optimal combination of aesthetics, functionality, and durability. Thanks to this team, we can flexibly tailor structures to meet the customer’s needs.

Within the project office, work preparation plays a crucial role in translating designs into production. This involves determining how the product can be manufactured efficiently and to a high-quality standard. In project management, having a dedicated point of contact is essential, as we operate in a project-driven industry where clear communication and efficient coordination are vital. This ensures that customers are well guided throughout the entire process and always know what to expect.

Production

In our modern production facilities, we combine advanced machinery with high-quality craftsmanship to manufacture masts that meet the strictest standards. This combination allows us to efficiently handle large volumes while still offering flexibility and customization. From the smallest components to the complete structure, we ensure precise fabrication and finishing. At VDL Mast Solutions, we continuously invest in our people and our machinery to optimize production processes and deliver high-quality, tailor-made mast solutions to our customers.

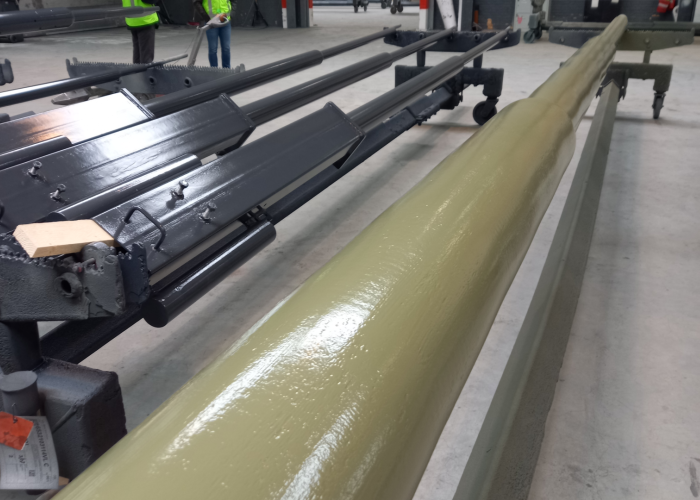

Preservation

We place great importance on the lifespan of our masts and therefore offer various preservation methods, including our innovative DCC coating. This coating significantly extends the mast’s lifespan and provides protection against corrosion and other environmental factors. To further enhance protection, following the Kaal DCC coating, we offer an additional durable and wear-resistant product to safeguard the mast base and the ground section: HMR® ground-level and base protection. In addition to HMR®, we also equip masts with conventional ground-level protectors, such as Fibaroll banding, heat-shrink sleeves, or asphalt/fiberglass banding.

Transport & Efficient Installation

Our logistics organization ensures that your masts are delivered on time and efficiently to their destination anywhere in Europe. Our modern transport fleet, equipped with truck-mounted cranes, enables us to handle both standard transport and long or exceptionally long transports. Where necessary, we combine this with external transport to provide maximum flexibility.

For installation, we work with experienced assembly teams who ensure professional installation, whether it involves a simple placement or a complex mounting project. Our Multi-Purpose Truck (MPT) allows masts to be installed efficiently, with all necessary equipment carried on a single truck combination. This significantly reduces the number of vehicles required and contributes to a more sustainable execution. Our project manager coordinates all details in advance so the installation team can start fully prepared. Safety is always our top priority—for our colleagues as well as the surrounding environment.

Fundation Methods: Sustainable & Innovative

The tubular pile foundation is a specialty of VDL Mast Solutions and is carried out entirely in-house, from design to implementation, using specialized equipment. This method offers numerous advantages:

No soil disposal required, minimizing ecological impact.

Small footprint, ideal for locations with limited space.

Installed within a single day (or part of a day) and immediately fully loadable.

Fully recyclable and easy to remove as a whole.

With this innovative foundation method, we can install masts quickly and in an environmentally conscious way, without prolonged disruption to the surroundings. This makes the tubular pile foundation ideal for situations where speed, minimal impact, and sustainability are crucial.

Inspection and Maintenance

At VDL Mast Solutions, our involvement does not end after the mast is installed. We offer comprehensive inspection and maintenance services to ensure safety and keep maintenance costs manageable.

Our specialists carry out thorough visual inspections on various types of masts. This also includes specific checks, such as coating thickness measurements and inspections of fall protection systems. In addition to inspections, we provide the necessary maintenance and repairs, including structural calculations, replacement and installation of components, relocation or dismantling of masts, and repair work on-site and at height.

Refurbishing

Sustainability and safety are central to our approach. In addition to developing new mast designs and adapting existing models, we also offer the possibility of refurbishing. This means giving existing masts and structures a second life by renovating, upgrading, and re-optimizing them for long-term use. A key advantage is that we carry out the entire refurbishing process in-house, without intermediate transport. This increases efficiency, reduces ecological impact, and ensures consistent quality.

Before reconditioning, the masts are inspected and evaluated for their new application, as well as for the necessary refurbishing work. This process mainly focuses on preservation, which we restore, reapply, or reinforce as needed. We favor High Mechanical Resistance (HMR), a high-quality base and ground-level protection that limits the degradation of steel around and below ground level, resulting in a significantly extended lifespan.

After reconditioning, the masts are re-certified and provided with the mandatory NEN-EN-40 declaration, ensuring safety and durability are maintained.